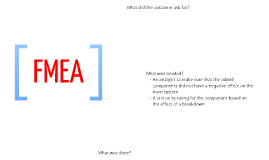

FMEA

Transcript: x SEVERITY :- importance of effect on customer requirements 1 = Not severe, 10 = Very severe OCCURRENCE :- freq. with which given failure cause occures 1 = Not likely, 10 = Very likely DETECTION :- ability to detect failure cause 1 = Easy to detect, 10 = Not easy to Detect Why FMEA ? When new systems, products, and processes are being designed When existing designs or processes are being changed When carry-over designs are used in new applications After system, product, or process functions are defined, but before specific hardware is selected or released to manufacturing Rating Scales List of actions to prevent causes or detect failure modes History of actions taken The FMEA FORM Allows us in identifying areas of our process that impact most of our customers Helps us identify how our process is most likely to fail Points to process failures that are most difficult to detect Application Examples RPN is the product of the severity, occurence, and detection scores Why FMEA ? Learning Objectives Rating Scales Risk Priority Number (RPN) DETECTION What is a Failure Mode ? A Failure Mode is : The way in which the component, subassembly, product,input, or process could fail to perform its intended function. Things that could go wrong A structured approach to: Identifying the ways in which a product or process can fail Estimating risk associated with specific causes Prioritizing the actions that should be taken to reduce risk Evaluating design validation plan (design FMEA) or current control plan (process FMEA) C&E MATRIX PROCESS MAP Process History Procedures Knowledge Experience A team approach is necessary. Team should be led by the process owner who is the responsible engineer or technical person, or other similar individual familiar with FMEA. The following should be considered for team members : --Design Engineers --Operators --Process Engineers --Reliability --Materials Suppliers --Suppliers RPN SEVERITY FAILURE MODE & EFFECT ANALYSIS (FMEA) MANUFACTURING: A manager is responsible for moving a manufacturing operation to a new facility. He/She wants to be sure the move goes as smoothly as possible and that there are no surprises. DESIGN: A design engineer wants to think of all the possible ways a product being designed could fail so that robustness can be built SOFTWARE: A software engineer wants to think of possible problems a software product could fail when sacled up to large databases. FMEA: A Team Tool There are a wide variety of scoring "anchoring", both quantitative or qualitative Two types of scales are 1-5 or 1-10 The 1-5 scale makes it easier for the teams to decide on scores The 1-10 scale may allow for better precision in estimates and a wide variation in scores (most common) FMEA Inputs & Outputs INPUTS Benefits of FMEA An FMEA: Identifies the ways in which a product or process can fail Estimates the risk associated with specific causes Priortizes the action that should be taken to reduce risk FMEA is a Team Tool There are two different types of FMEAs: Design Process Inputs to the FMEA include several other Process tools such as C&E Matrix and Process Map. SUMMARY FMEA When to conduct an FMEA ? To understand use of FMEA To learn the steps to developing FMEAs To summarize the different types of FMEAs To learn how to link the FMEA to other Process tools x OCCURENCE = Types of FMEAs Design Analysis product design before release to production, with a focus on product function. Analysis systems and subsystems in early concept and design stages Process Used to analyse manufacturing and assembly processes after they are implemented OUTPUTS Methodology that facilitates process improvement Identifies & eliminates concerns early in the development of a process or design Improve internal & external customer satisfaction Focuses on prevention FMEA may be a customer requirement (likely contractual) FMEA may be required by an applicable Quality Management System Standard (may be ISO)