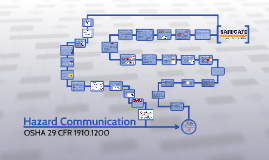

Hazard Communication

Transcript: >> Since May 23, 1998, OSHA has had guidelines to inform us on hazardous workplace substances. >> The 1910.1200 standard covers general industry, shipyards and marine terminals, longshoremen, construction, chemical manufacturers, importers and any and all other employers and employees exposed to chemical hazards. >> Most of the standard covers chemical manufacturers, but non-producers have to establish a workplace program and communicate that information to the workers. Appendix E of 1200 provides guidelines for this. >> Agents which act on the blood or hematopoietic system: deprive body tissue of oxygen >> Agents which damage the lungs >> Hepatotoxins: liver damage >> Nephrotoxins: kidney damage >> Neurotoxins: nervous system effects >> Reproductive toxins, including teratogens (damage fetuses) and mutagens (damage DNA) >> Cutaneous hazards: skin damage >> Eye hazards >> Inhalation, injection, ingestion and absorption are exposure methods >> Ensure that SDS's are readily accessible to workers. >> Keep SDS binder on-site or store electronically for workers to access. >> Designate person(s) responsible for obtaining and maintaining the SDS's. Consider ALL hazards: Definitions To Know Acute: rapid effects, as a result of short-term exposures, of short duration. Chronic: effects as a result of long-term exposure, of long duration. Corrosive: visible destruction or irreversible damage to body tissue, including acids and caustics (bases) Employers must inform employees of: >> Training requirements of this section. >> Operations in their work area where hazardous chemicals are present. >> The location and availability of the written "Hazardous Communication Program". Section 1: Identification >> Product identifier on label >> Responsible parties/manufacturer name, address & phone number >> Recommended use of the chemical and any restrictions for it GHS Standard - Safety Data Sheets (SDS) 16 Section Format >> Identity of the chemical >> Appropriate hazard warnings, including: - Message, picture, or symbol - Hazards of the chemical - Which organs are affected - Must be in English, may be in other languages >> Name and address of responsible party >> In 2012, OSHA revised its Hazard Communication Standard (HCS) to align with the United Nations' Globally Harmonized System of Classification and Labeling of Chemicals (GHS). >> New standard classifies chemicals according to their health and physical hazards. >> New label elements & SDS requirements will improve worker understanding of hazards associated with chemicals in the workplace. >> Phase in dates for compliance are from 12/01/2012 to 06/01/2016. The rule does not require employers to maintain records of employee training, but many employers do so to help you to monitor your program to ensure that all employees are properly trained. GHS Standard - Safety Data Sheets (SDS) 16 Section Format You may want to discuss each chemical if there are only a few chemicals in the workplace. >> Based on the hazard categories (e.g. - flammable liquids, corrosive materials, carcinogens) >> If there are a large numbers on chemicals >> If the chemicals change frequently SDS Sheets? Classifications >> It makes sure that all employers receive the information they need. >> Inform and train their employees. >> Ensures all employees are provided with the necessary hazard information. Section 3: Composition/Information on Ingredients >> Chemical substances and mixtures (chemical name, CAS number) >> Trade secrets All employees who may be exposed to hazardous chemicals MUST: >> OSHA.gov says: "The HCS provides workers the right-to-know concerning the hazards and the identities of the chemicals they are, or may have the potential to be, exposed to in the workplace. GHS Standard - Safety Data Sheets (SDS) 16 Section Format Who is covered by 1910.1200? Section 9: Physical and Chemical Properties How Do We Do This? About SDS Sheets GHS Standard - Safety Data Sheets (SDS) 16 Section Format Labels >> Employees need to know the hazards and the chemicals they are exposed to at work, as well as what protective measures are available. Class 3: Liquids Employee Responsibility Class 1: Explosives Levels 1.1 to 1.6 Class 2: Gases Class 5: Oxidizers and Organic Compounds Class 6: Toxic Materials and Infectious Substances Class 7: Radioactive Material Class 8: Corrosive Materials Section 8: Exposure Controls/Personal Protection >> OSHA's Permissible Exposure Levels (PEL's) >> Threshold Limit Values (TLV's) >> Engineering Controls >> PPE >> Have an explanation of the HazCom program, including labels, SDS, how to obtain and use the available information. >> Explain physical/health hazards of chemicals. >> Provide protective measures, such as PPE, work practices, & engineering controls. >> Explain how to detect the presence or release of a hazardous chemical ( monitoring devices, observation or smell). Section 2: Hazard(s) Identification >> Pictograms >> Signal Words >> Classification of Hazardous