Hot Air Balloon

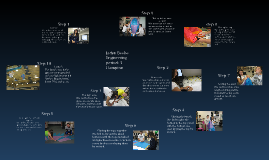

Transcript: Step 1 Step 2 Step 3 Step 4 Step 1: Quiz + Research Paper The first step of the assignment was to take a quiz on the history and mechanics of the Hot Air Balloon with a passing grade. The class was given a sheet of paper with the questions from the Quizstar and it was our job to search the internet for all the answers. Once that was completed, we were allowed to take the Quiz up to three times until a decent grade was achieved. I searched all the answers (finding the majority of them) then took the online quiz. After a couple of times, I got a low B grade, but I took it an extra attempt to at least get an A, considering there may have been some important terms I got incorrect, and I got a 92% as my final score. Step 2: Blueprinting After our Quizstar was completed, we were assigned a partner to cooperate with for the rest of the project. There would be some cases where a partner’s cooperation would be needed to process the build more smoothly, but first they would decide on the color panels the balloon would have as well as the order for the blueprinting on a paper given to them pre-sketched on, rather than graph paper. By the time I was assigned my partner, he was just about done with his own quiz, so I got his opinion on the colors and wrote the labels onto the Balloon Design Worksheet, anticipating how the panels would be put together, how the gores would end up, and in which order. Eventually, we agreed on using blue, green, and purple for our color selections. Step 3: Cutting/Tracing/Gathering the Panels Gathering, tracing, and cutting the panels would require cautious work with the tissue paper. The very beginning of the process was cutting an outline or base panel of both the bottom and top versions, and then gathering our twenty sheets of tissue paper (having 20 panels equal to 10 gores.) Once we had those materials, the task was to trace ten bottom panels, ten tops, and cut them out as neatly as possible without wrinkling or tearing the paper. This step went more smoothly than I thought it would be, even though a few of our panels needed some patching in the end. The only problem was that it took a period longer to cut than necessary, but after coming in during lunch for some extra work time, it turned out well enough. Step 4: Gluing the Panels to create Gores Gluing the bottom panel over the top by an inch was the first of three gluing steps. According to how the blueprints looked, two panels would be combined to create one gore of the color choice. Once ten gores were ready, we had to glue all the bottom gores side-by-side by one inch as well, so that it’d create a flower shape before finishing the envelope. Keeping track of all our panels and making sure we had enough tops and bottoms was a hassle if we didn’t stay organized, but even then I made several mistakes from gluing tops over bottoms, pasting together two of the same panels, and getting the color codes wrong. This step also took quite a bit of time, but the result was relieving. Tranforming into 3D from 2D Transforming a flat, 2D shape into a 3D object that would eventually lift off the ground was the most difficult part of the project. By this step, the bottoms of the gores have been glued and the only thing left to do with the envelope is paste the top panels together. One partner would do the gluing; the other keeping the panels leveled with each other until the last gores were combined, then the balloon shape would form. My partner and I took turns with the glue and keeping the tissue firm, and the first couples were harder than I thought they’d be, but with every gore we got done, it gradually became easier. It was more than a relief to have finished this step successfully and barely on schedule. Attaching the Rim The only thing to do in this step was to cut approximately a two foot long strand of firm paper. This would act as the rim for the bottom of the balloon and to attach it, a few staples would be needed over an inch or so of paper folded over the strand. This also solves any problems with uneven ends, to our benefit. Our rim was a bit longer than two feet, but it worked out fine with the assistance of my partner. I held the tissue paper and rim in place while he stapled the tissue to the stand several times for extra binding. (no picute) Tying the Insulator. This was probably one of the easiest parts of the project, as long as there was a diligent partner to help. All we had to do was cut a string about arm’s length and tie it around the top of our balloon. If done right, the hot air should be trapped inside the envelope, instead of escaping through the top. The hot air, when locked, would rise with the balloon, but if done incorrectly, there wouldn’t be chance that the balloon would ever lift off the ground. This step only took a few minutes and, thankfully, I had a good partner. He held the ends of the balloons while I tied the string around an extra couple of times just to assure the tightness. We cut the supplemental