Air Compressor

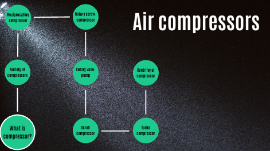

Transcript: Application of Air Compressor Supplying high-pressure clean air to fill gas cylinders Supplying moderate-pressure clean air to a submerged surface supplied diver Supplying moderate-pressure clean air for driving some office and school building pneumatic HVAC control system valves Supplying a large amount of moderate-pressure air to power pneumatic tool Filling high pressure air tanks (HPA), for filling tires Produce large volumes of moderate-pressure air for large-scale industrial processes (such as oxidation for petroleum coking or cement plant bag house purge systems) Demo Video Heavy noise on compressor Compressor clutch is not moving Compressor overheat Slugging Oil not returning to system As the piston reaches top, the pressure starts to fall and the delivery valve starts to close. The residual compressed air remaining in the space again starts to expand as the piston moves down continuing the next cycle When the compressor stops or idles for some time, it is always assumed that there is some residual compressed air left in the cylinder space. This residual air expands when the piston moves down. The pressure drops in the cylinder space at a particular point as the piston moves down, where the pressure inside the cylinder becomes lesser than the atmospheric pressure. Thus this difference in pressure makes the suction or inlet valve open. DJJ6153 Mechanical Component and Maintenance Logeswaran s/o Govindarajan Arvind Naidu A/L Beng tissen Rajamunirant s/o Kandasamy Prem Kumar s/o Ramachandren Samuel Moses s/o Moheneswaran Step 1 Air Compressor An air compressor is a device convert power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air. One of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When tank pressure reaches its upper limit the air compressor shuts off. The compressed air, then, is held in the tank until called into use. The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank Characteristics of compressors Air Compressor Operation Step 3 1. Dynamic Centrifugal Axial 2. Positive Displacement I. Reciprocating Single-acting Double-acting II. Rotary Helical-Screw Liquid-Ring Scroll Sliding-Vane Lobe Air Compressor Diagram Types of Compressor Failure symptoms on compressor This opening of inlet valve allows fresh air to be drawn inside the cylinder space as the piston still continues to move in the downward direction. The inlet valve will remain open till there is pressure difference between the atmosphere and inside of the cylinder space. As the pressure difference starts to reduce, the inlet valve starts slowly closing. The inlet valve closes completely when there is no pressure difference and then the piston reaches bottom dead center (BDC), and it starts to travel in an upward direction. At this position, both the inlet and delivery valve remains closed. Thus as the piston moves up, the pressure starts to build inside the cylinder space • High precision machining to ensure the compressor confirm with standard • Steady operation, small vibration, low noise and excellent stability • Electrical motor protect device • Wear resistant driver gear • Chrome plated piston rings • Aluminium pistons • Efficient valve plate design • Low energy consumption Example of check list for compressor maintenance The delivery valve starts to open when there is a pressure difference between the cylinder space and air receiver. Let us assume the air receiver is at a pressure of 7 bar. The delivery valve will not open until the pressure inside the cylinder space is slightly above 7 bar. As the piston moves in upward direction, the pressure increases and at some point the pressure grows beyond 7 bar making the delivery valve open. Thus the compressed air is delivered into the air receiver. Introduction of Air Compressor Step 4 Step 2